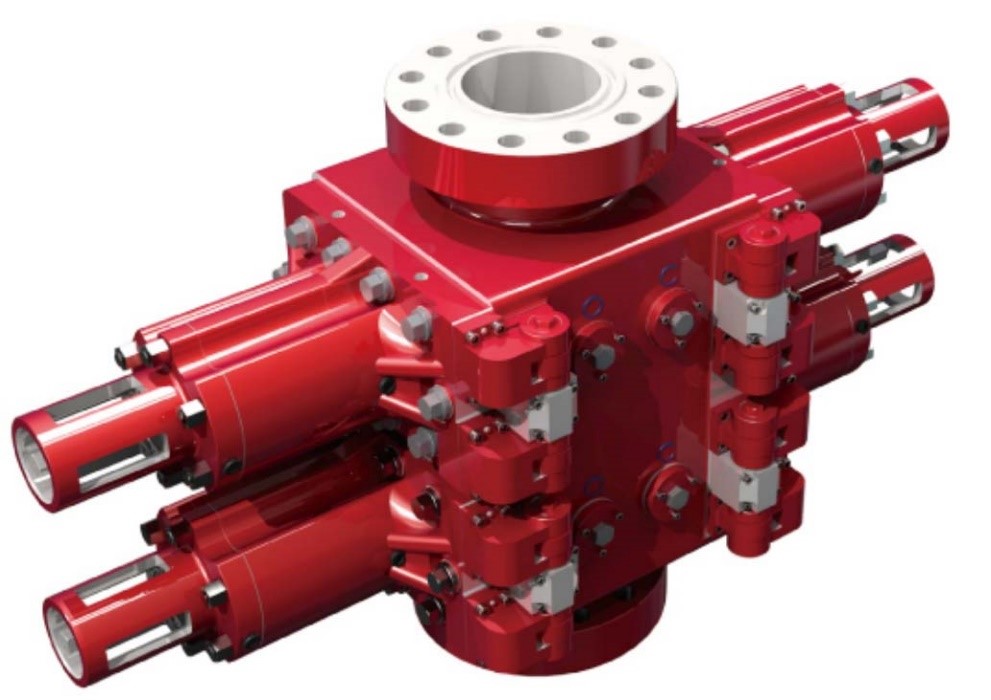

During oil drilling, immense underground pressures pose a constant risk of uncontrolled flow – a blowout. This is where the Blowout Preventer (BOP) becomes indispensable. It is a massive, specialized valve stack mounted directly on the wellhead, acting as the last line of defense against catastrophic releases of oil, gas, or drilling fluids.

The BOP’s core function is to seal the wellbore swiftly and reliably if abnormal pressure is detected or control is lost. It achieves this through powerful hydraulic rams and sealing elements. Key components include:

1. Ram Preventers: Feature opposing steel blocks (rams) that close around the drill pipe, seal the open hole, or even shear (cut) the pipe in emergencies to completely seal the well. Types include pipe rams, blind rams, and shear rams.

2. Annular Preventer (Bag-Type): Uses a reinforced rubber packing element that closes concentrically around the drill pipe (or kelly) like a diaphragm, forming a pressure-tight seal on irregular shapes or even an open hole.

3. Control Systems: Remotely operated hydraulic or electro-hydraulic systems provide the immense force needed to activate the rams or annular element rapidly from a safe distance.

BOP stacks are rigorously tested and rated for the extreme pressures expected in the specific well. Their reliability is paramount for protecting personnel, the environment, and expensive drilling equipment. A functioning BOP stack is non-negotiable for safe drilling operations, especially in high-pressure zones or deepwater environments. It is the ultimate safety barrier against one of the oilfield’s most dangerous hazards.

Post time: Jun-19-2025