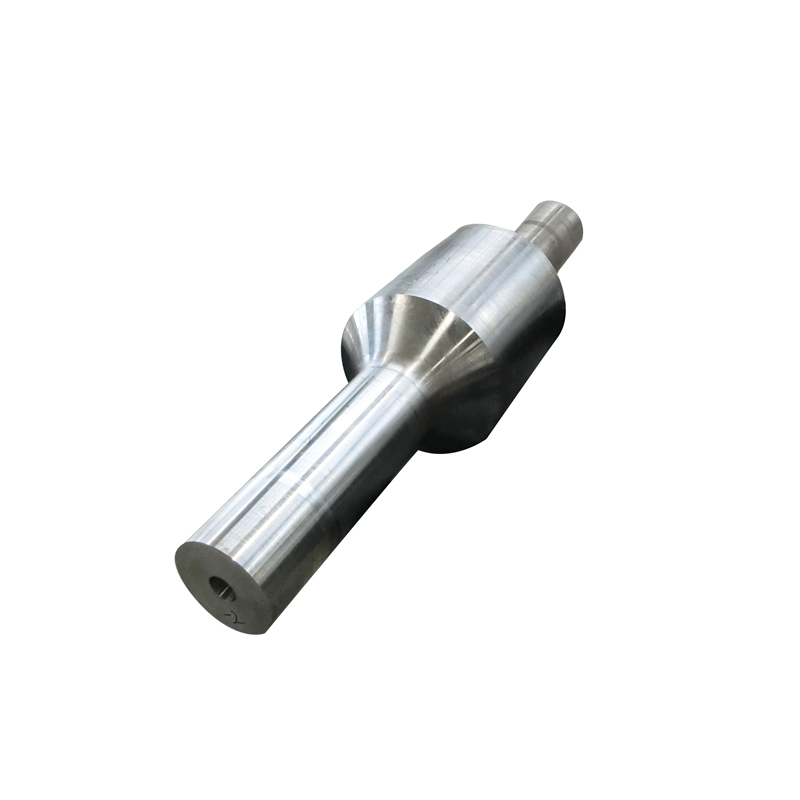

Integral Stabilier 4145H

Our Advantages

20-year plus experience for manufacturing;

15-year plus experience for serving top oil equipment company;

On-site quality supervision and inspection.;

For the same bodies of each heat treatment furnace batch, at least two bodies with their prolongation for mechanical performance test;

100% NDT for all bodies;

Shop self-check + WELONG’s double check, and third-party inspection (if required.)

Product Description

WELONG’s Stabilizer Body: Superior Customization, Unmatched Quality Control and Exceptional After-Sales Service

With 20 years of manufacturing experience, WELONG takes pride in offering top-of-the-line products, including our renowned “WELONG’s stabilizer body.” We understand the importance of meeting our clients’ specific requirements, which is why our stabilizer bodies can be customized based on customer-provided drawings. Whether it’s machining threads or any other custom features, we ensure precise execution.

Quality is paramount at WELONG, and we leave no stone unturned to maintain it. All raw materials used in the production of our stabilizer bodies are sourced from reputable large steel mills to guarantee their reliability and durability. The steel ingots undergo electric furnace smelting and vacuum degassing processes to meet our stringent standards. For utmost transparency, we report any element exceeding 0.25% in the chemical composition, while ensuring that the total amount of residual elements remains below 1.00%.

Forging is a critical step in the manufacturing process, and at WELONG, we adhere to strict guidelines. Our stabilizer bodies are forged using hydraulic or water presses, without employing electro-hydraulic hammers, air hammers, or rapid forging machines. The forging ratio is maintained at a minimum of 3:1, ensuring optimal strength and structural integrity. We strive for superior grain size with a rating of 5 or better, while cleanliness is assessed using ASTM E45 Method A or C to determine average inclusion levels.

To ascertain mechanical properties, we conduct tests 1″ below the surface. Charpy V-notch Impact Property testing is performed at a temperature of 20℃±3℃ (70°F), with values derived from an average of three separate specimen tests. Hardness testing is conducted on each body, ensuring any decarburization is removed by grinding the test area. Additionally, ultrasonic testing is carried out according to ASTM A587 using the flat-bottom hole procedure, covering both direct and oblique angles.

Adhering to API 7-1 standards, WELONG’s stabilizer bodies guarantee exceptional performance and reliability in various applications. Before delivery, each body undergoes a thorough cleaning process to ensure pristine internal and external surfaces. After surface cleaning with appropriate solvents, they are allowed to dry completely before being coated with rust-resistant oil. They are then carefully wrapped first with white plastic cloth and further secured with green striped fabric to prevent leakage and minimize any potential damage during transportation. For long-distance sea shipping, the bodies are packaged using iron racks to provide optimal support and protection.

At WELONG, we prioritize customer satisfaction, offering not only superior products but also excellent after-sales service. Our experienced team ensures that your needs are met throughout the entire process, from customization to delivery and beyond. With our strict quality control measures, you can trust in the reliability and performance of WELONG’s stabilizer bodies for your specific requirements.