Heat treatment is a commonly used method in metal material processing, which changes the microstructure and properties of materials by controlling their heating and cooling processes. The iron carbon equilibrium phase diagram is an important tool for studying the microstructure transformation laws of steel materials at different temperatures. Although mastering the iron carbon equilibrium phase diagram is very helpful for heat treatment work, mastering this aspect alone is not enough.

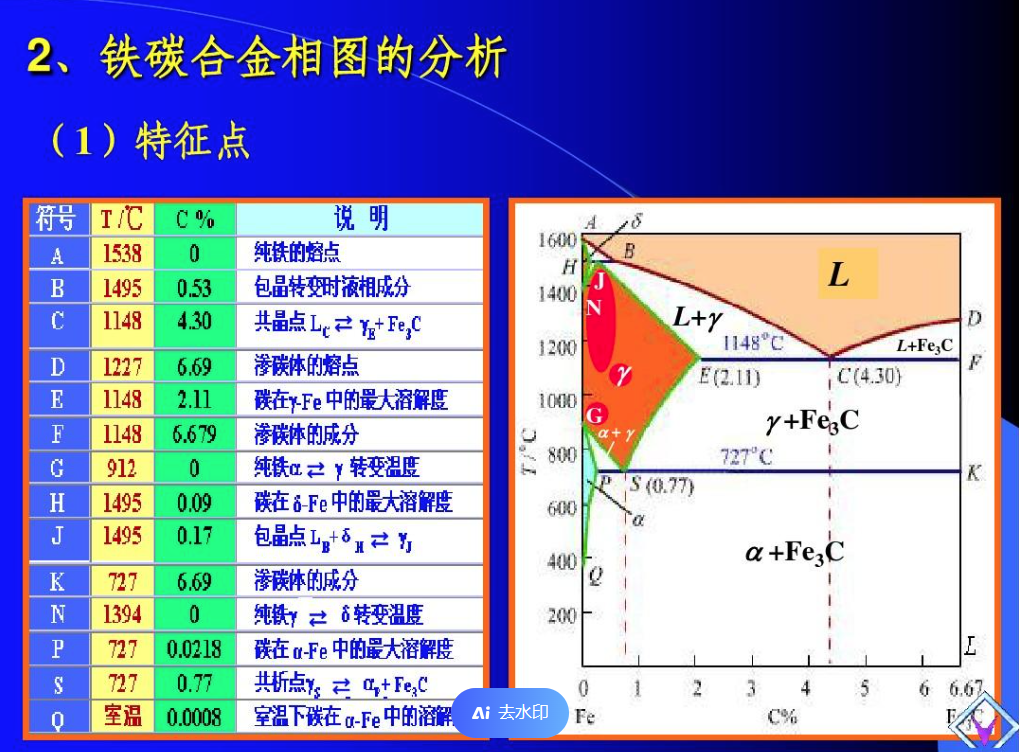

Firstly, the iron carbon equilibrium phase diagram is a chart that describes the interaction between carbon and iron. It displays the possible phase composition and phase transformation of steel materials at different temperatures and carbon contents. We can learn about the solid phase composition, phase transition temperature range, and phase transition mode of steel at different temperatures from it. This is crucial for the design and control of heat treatment processes, as different temperatures and cooling rates can lead to different microstructures and properties of materials.

However, learning heat treatment work goes far beyond understanding the iron carbon equilibrium phase diagram. The following are several aspects that need to be noted:

Understanding the phase transition laws of metals: In addition to the iron carbon equilibrium phase diagram, it is also necessary to understand the phase diagrams of other metals. Different metals undergo different phase transitions at different temperatures, and for heat treatment, it is necessary to understand the characteristics of each metal.

Familiar with heat treatment process: Learning heat treatment requires mastering various heating and cooling processes, such as annealing, normalizing, quenching, etc. Each process has specific temperature, time, and cooling rate requirements to achieve the required material properties.

Understanding the relationship between organization and performance: Understanding the relationship between material organization structure and performance is the core of heat treatment. By controlling the microstructure of materials, they can have better mechanical properties, corrosion resistance, and other characteristics.

Mastering testing and analysis methods: Learning heat treatment also requires mastering some testing and analysis methods, such as metallographic microscopy observation, hardness testing, tensile testing, etc. These methods can help us evaluate the structure and properties of materials, thereby optimizing the heat treatment process.

In short, mastering the iron carbon equilibrium phase diagram is only a part of heat treatment work. In addition to understanding phase diagrams, it is also necessary to master the laws of metal phase transformation, heat treatment processes, the relationship between microstructure and properties, as well as testing and analysis methods. Only by comprehensively mastering these knowledges can good results be achieved in heat treatment work and meet various material performance requirements.

Post time: Dec-29-2023