News

-

What are the advantages of forging piston rods?

Forged piston rods are renowned for their superior strength and reliability, making them a preferred choice in various industries. One of the primary advantages of forged piston rods lies in the inherent grain structure resulting from the forging process. Unlike cast or machined piston rods, whic...Read more -

How to evaluate the quality of forgings?

Evaluating the quality of forgings involves assessing several key aspects to ensure that the final product meets the required standards and specifications. Here are some common methods used to evaluate forged components: Dimensional Accuracy: One of the primary indicators of forging qualit...Read more -

The Importance of Heat Treatment for Shafts’ Strength and Durability

Shafts are critical components in various mechanical systems, bearing the weight and transmitting the power of vehicles or machinery. To enhance their strength and durability, post-processing heat treatments are often employed. These procedures involve heating the Shafts to specific temperatures ...Read more -

The Importance of Chromium Content in Stainless Steel

Stainless steel is renowned for its durability, corrosion resistance, and aesthetic appeal. However, not all steel can claim the prestigious “stainless” prefix. One crucial element that determines whether steel qualifies as stainless is chromium content. Chromium plays a pivota...Read more -

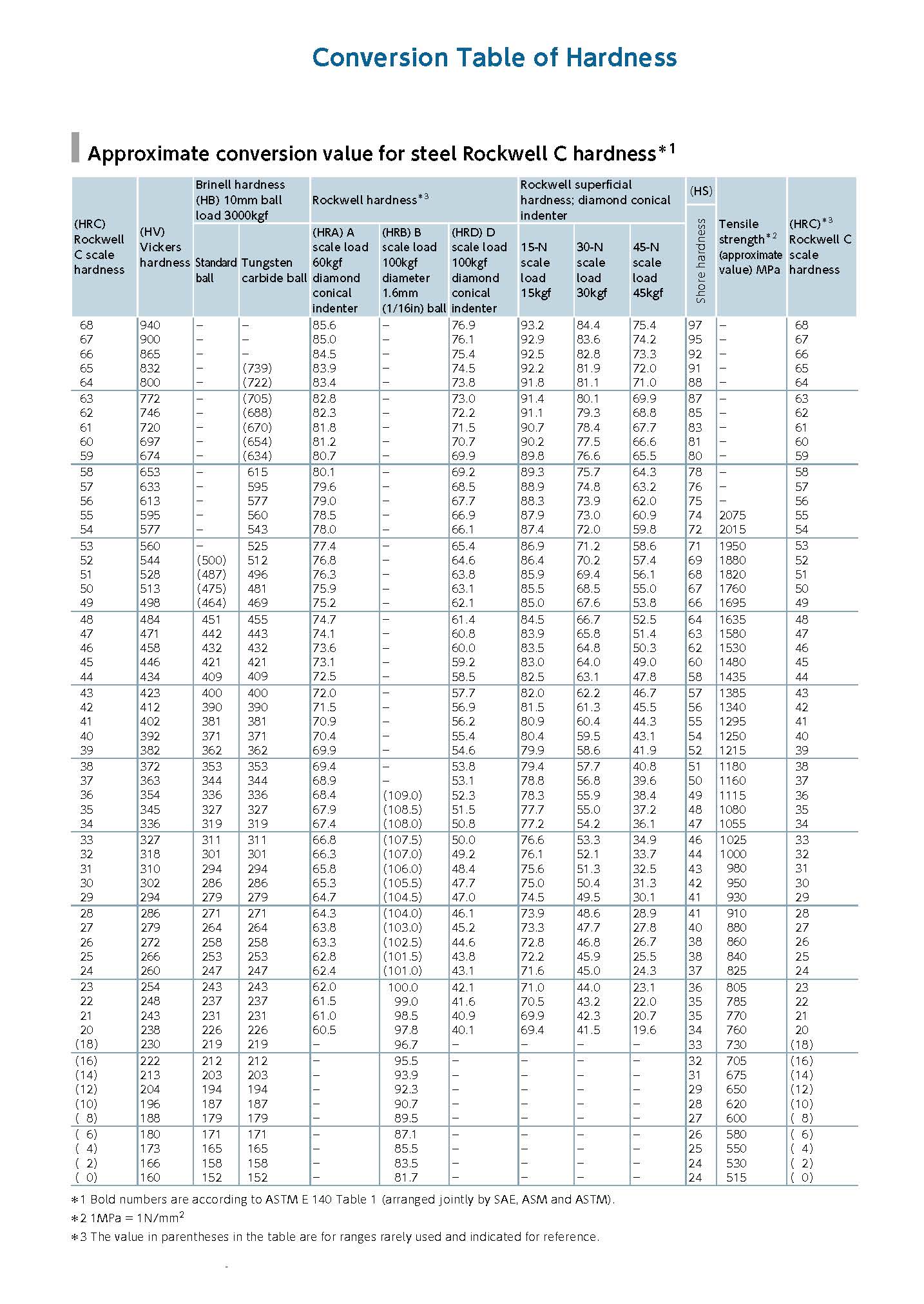

Conversion Table of Hardness

Read more -

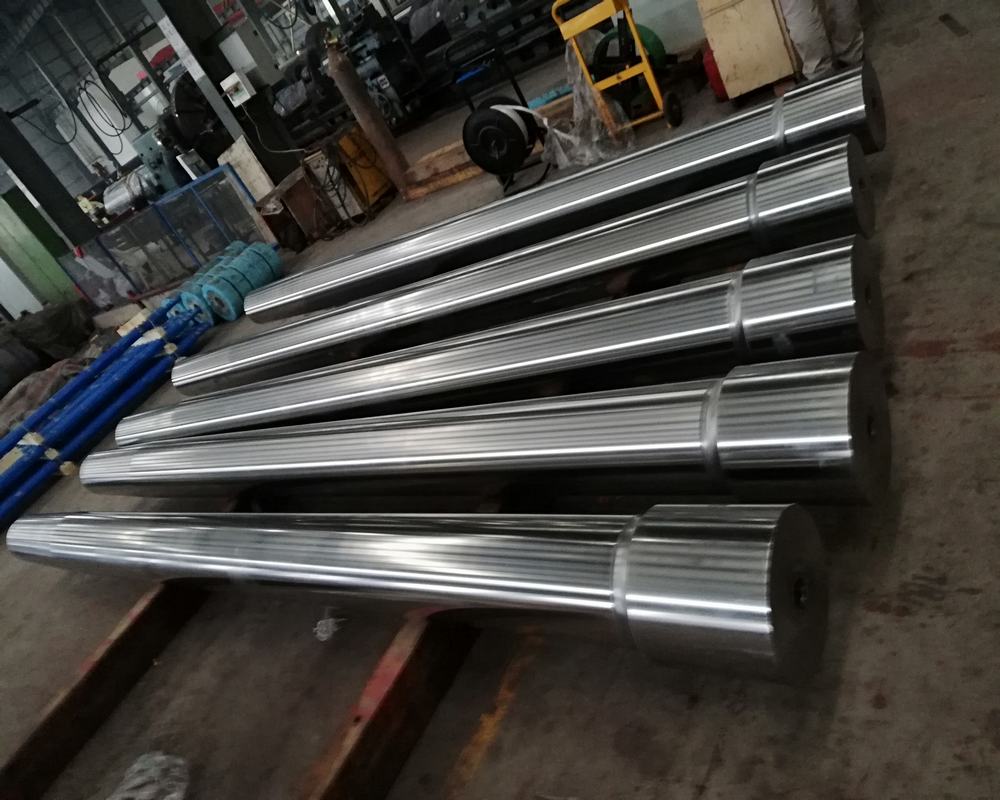

What is a Forged Shaft?

A forged shaft is a crucial component used in various industrial applications, known for its strength, durability, and resilience. This type of shaft is manufactured through a process called forging, where metal is shaped by applying compressive forces. Let’s delve deeper into the character...Read more -

The Relationship between Strength and Weight of Balanced Forging Rolls

It is crucial to balance the relationship between the strength and weight of the forged product when designing forging rolls. Forging rolls, as important components in undertaking large-scale mechanical equipment, play a crucial role in industrial production. To ensure its normal operation and lo...Read more -

Factors determining the most suitable forging roller material

When selecting the most suitable forging roller material, multiple factors need to be considered, including the material’s mechanical properties, wear resistance, heat resistance, thermal conductivity, cost, etc. The following are some main considerations: 1. Mechanical performance Strengt...Read more -

Forged spindle tube

In the world of engineering and manufacturing, there is a constant pursuit to develop materials and components that possess superior strength and durability. One such component that plays a crucial role in various industries is the forged spindle tube. This article will delve into the characteris...Read more -

Forged pipe mold

Forged pipe molds, also known as forging molds or forging dies, are key tools used to manufacture metal pipes. It plays a crucial role in the metal forging process, being able to heat, shape, and cool the metal raw materials to form the desired pipe shape. Firstly, let’s understand the basi...Read more -

Quality issues of shaft forgings and ways to improve machining accuracy

Finding the causes of quality problems: To understand the quality control of the machining process of shaft forgings, it is necessary to first understand the causes of quality problems during the mechanical machining process. Process system error. The main reason is to use approximate methods fo...Read more -

How do heating temperature and insulation time affect the forging process of steel ingots?

The influence of heating temperature and insulation time on the forging process of steel ingots. Heating temperature and insulation time are the two main parameters in the forging process of steel ingots, which directly affect the plasticity of the blank and the quality of the final product. When...Read more