News

-

The book club of< Only One Thing in Life>

On October 25th, the October Book Club event took place in the company’s conference room as scheduled. The theme of this book club was “There is Only One Thing in Life,” and the company’s leadership, business, procurement, inspection, and other teams all attended the even...Read more -

Open forging parts

The basic processes of free forging include upsetting, elongation, punching, bending, twisting, displacement, cutting, and forging. Free forging elongation Elongation, also known as extension, is a forging process that reduces the cross-sectional area of the billet and increases its length. Elong...Read more -

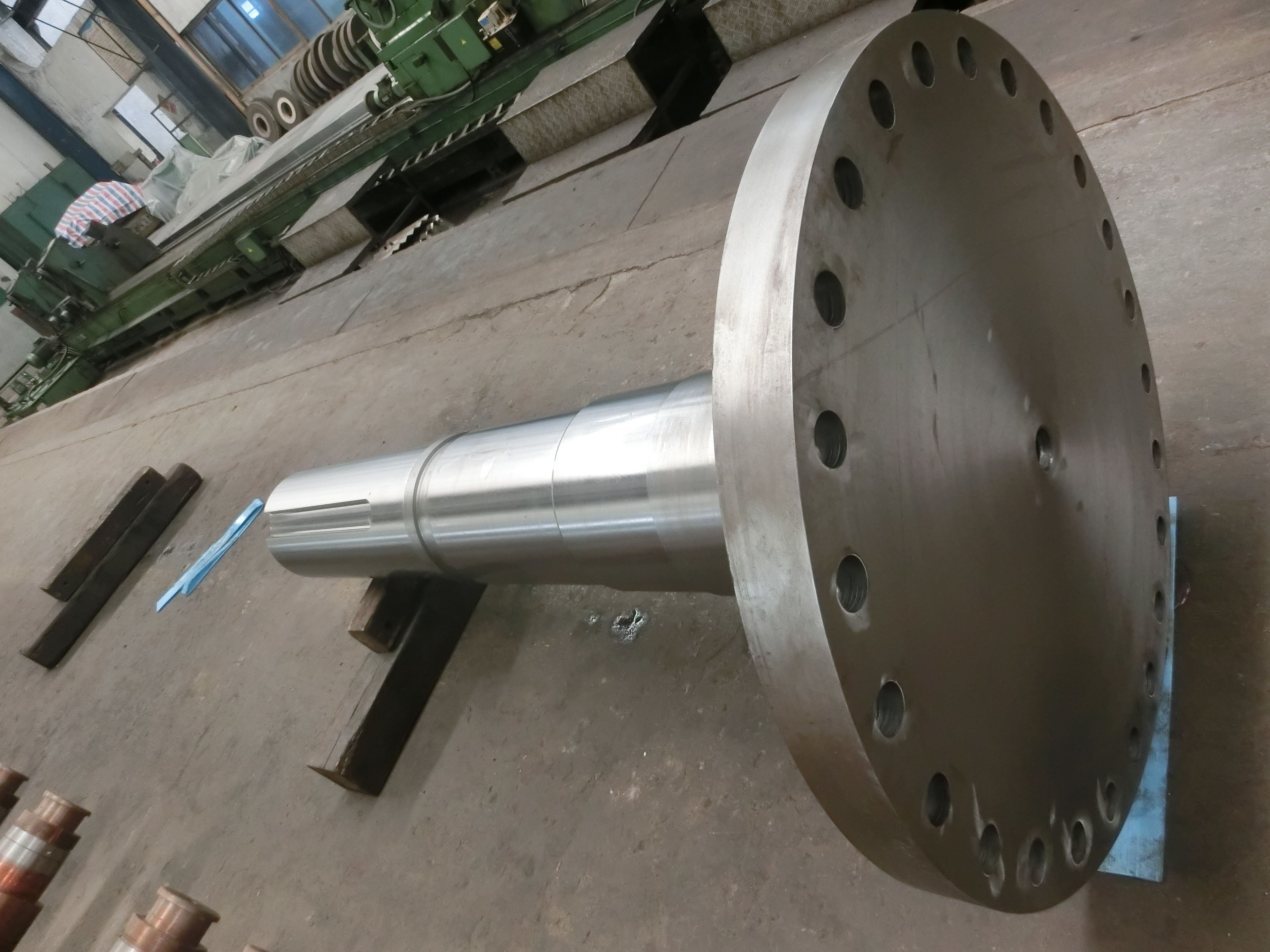

Forging for rotor of industrial steam turbines

1. Smelting 1.1 For the production of forged parts, alkaline electric arc furnace smelting followed by external refining is recommended for steel ingots. Other methods ensuring quality can also be used for smelting. 1.2 Prior to or during the casting of ingots, the steel should unde...Read more -

Normalizing of the forging part

Normalizing is a heat treatment that improves the toughness of steel. After heating the steel components to a temperature of 30-50 ℃ above the Ac3 temperature, hold them for a period of time and air cool them out of the furnace. The main characteristic is that the cooling rate is faster than anne...Read more -

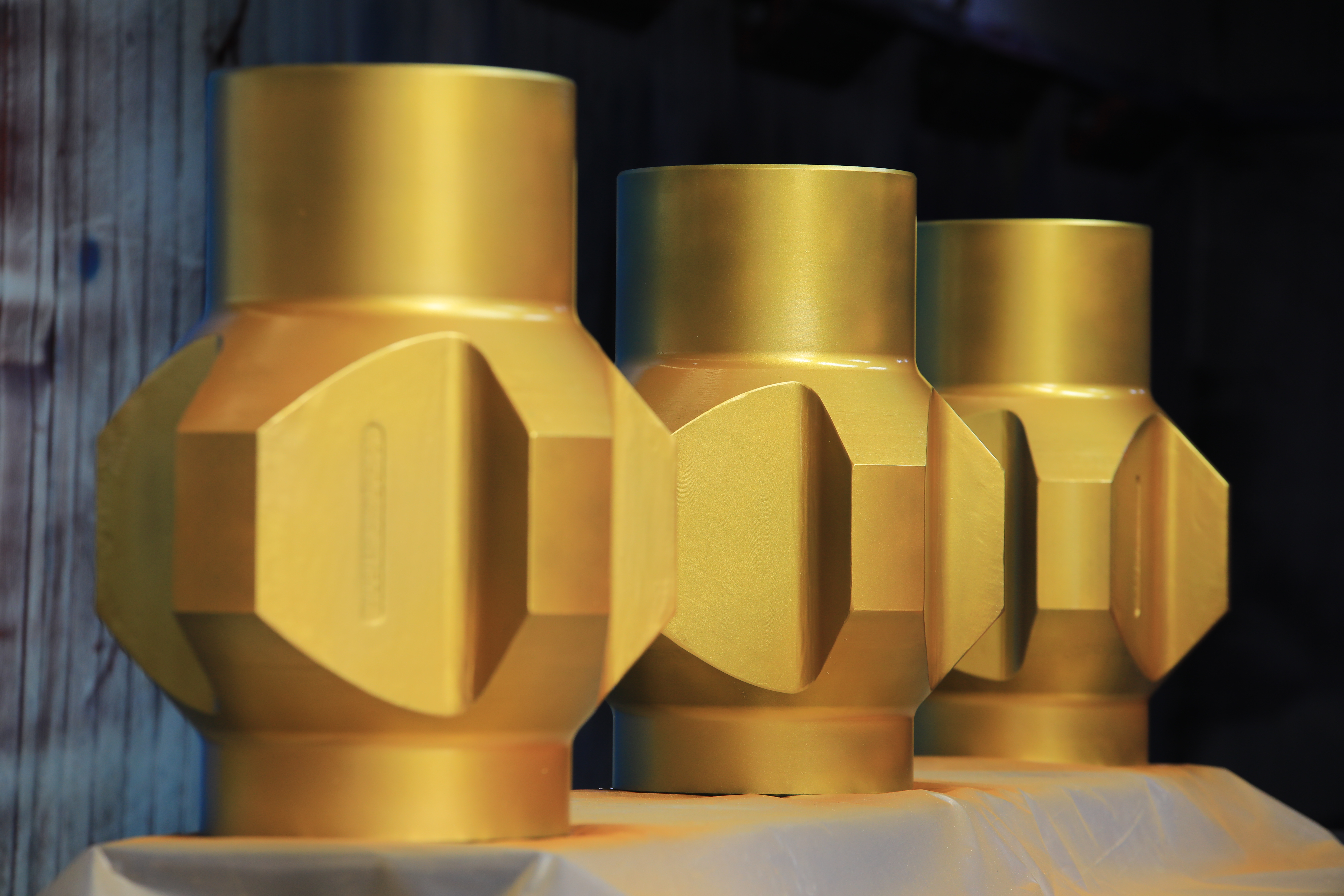

Some Technical Spec For forged tower flanges of wind turbine

General Requirements Flange manufacturing companies must possess the technical capabilities, production capacity, and inspection and testing capabilities required for the products, along with at least two years of experience in the forging industry. Manufacturing Equipment Flange manufactu...Read more -

Temper brittleness during forging and processing of forgings

Due to the presence of temper brittleness during forging and processing of forgings, the available tempering temperatures are limited. To prevent brittleness from increasing during tempering, it is necessary to avoid these two temperature ranges, which makes it difficult to adjust mechanical prop...Read more -

What are the heating methods for shaft forgings?

Continuous moving heating is commonly used for induction heating of shaft forgings, while high-frequency quenching heating usually involves fixing the inductor while the forging moves. Medium frequency and power frequency heating, often moved by sensors, and the forging can also rotate when neede...Read more -

Saudi Arabia voluntarily reduces production

On August 4th, domestic Shanghai SC crude oil futures opened at 612.0 yuan/barrel. As of press release, crude oil futures rose 2.86% to 622.9 yuan/barrel, reaching a high of 624.1 yuan/barrel during the session and a low of 612.0 yuan/barrel. In the external market, US crude oil opened at $81.73 ...Read more -

US oil inventory fell more than expected, with oil prices rising by 3%

New York, June 28 (Reuters) – Oil prices rose about 3% on Wednesday as US crude oil inventories exceeded expectations for the second consecutive week, offsetting concerns that further interest rate hikes may slow economic growth and reduce global oil demand. Brent crude oil futures rose $1....Read more -

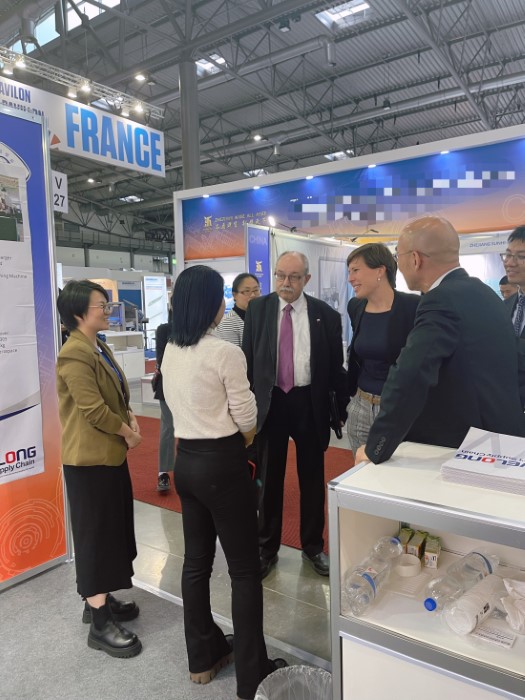

The Chinese Ambassador to the Czech Republic and the Minister of Commerce of the Czech Republic visited the Welong booth.

On October 10th, the 64th Brno International Engineering Fair opened grandly in Brno, the second largest city in the Czech Republic. In order to explore broader overseas markets and promote the Welong ‘s brand, the Welong team also sent two key business personnel to attend this exhibition. ...Read more -

Technical specifications for the main shaft forging of wind turbine generator

Smelting The main shaft steel should be smelted using electric furnaces, with refining outside the furnace and vacuum degassing. 2.Forging The main shaft should be directly forged from steel ingots. The alignment between the axis of the main shaft and the center line of the ingot should be main...Read more -

Non-magnetic integral blade type stabilizer

The development and production of nonmagnetic hard alloy materials are significant manifestations of new hard alloy materials. Hard alloy is made by sintering the refractory metal carbides of the IV A, V A, and VI A groups in the periodic table of elements (such as tungsten carbide WC), and the t...Read more