Customized Open Forging Part For Bit

Customized open bit forging advantage

• Forging over other manufacturing methods include greater strength, reliability, and durability, as well as the ability to produce complex shapes with tight tolerance.

• Both of forging size and shape are customized.

• Forging material stock is available based on the demanding quantity and plan.

• Material steel mill is audited per biennium and approved from our company WELONG.

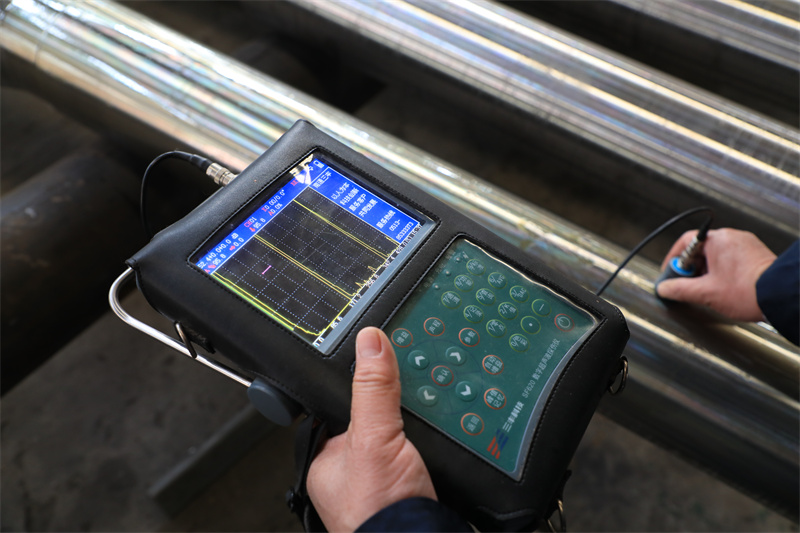

• Each stabilizer has 5 times nondestructive examination (NDE).

Main Material

• AISI 4145H MOD,4330,4130,4340,4140,8620 and etc.

Process

• Forging + Rough machining + Heat Treatment +Property Self-Testing + The third-party testing + Finishing Machining + Final inspection + Packing.

Application

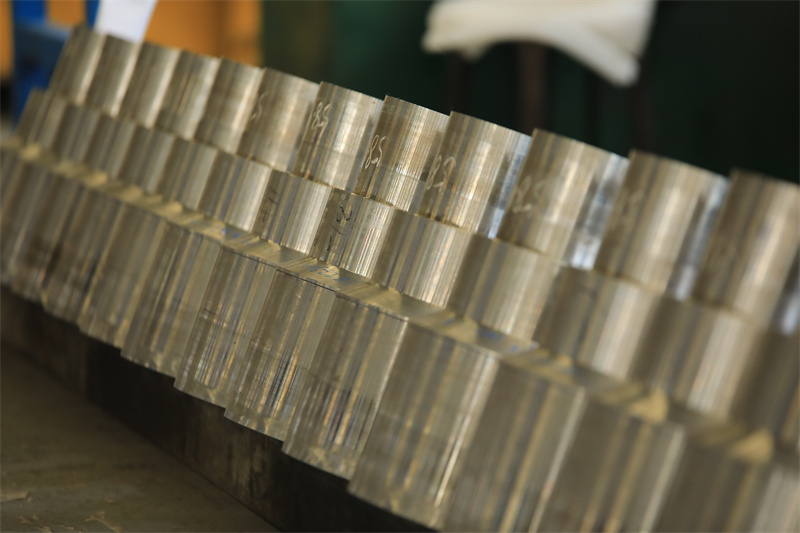

• Motor stabilizer forging, stabilizer forgings, bit forgings, forging shaft, forging ring and etc.

Forging size

• Max forging weight is about 20T. Max forging diameter is about 1.5M.

Customized open bit forging process

• Heating: The metal workpiece, typically in the form of a bar or billet, is heated to a suitable temperature to make it more malleable. This temperature varies depending on the specific metal being forged.

• Placing and Alignment: The heated workpiece is placed on an anvil or a flat surface, ensuring proper alignment for subsequent forging operations.

• Hammering: The blacksmith uses various types of hammers, such as a power hammer or hand hammer, to strike and shape the metal. The hammer blows, combined with skillful manipulation, deform the workpiece into the desired shape.

• Reheating: Depending on the metal's properties and the complexity of the desired shape, the workpiece may need to be reheated multiple times during the forging process to maintain its malleability.

• Finishing: Once the desired shape is achieved, additional operations like trimming, cutting, or other finishing touches can be performed.