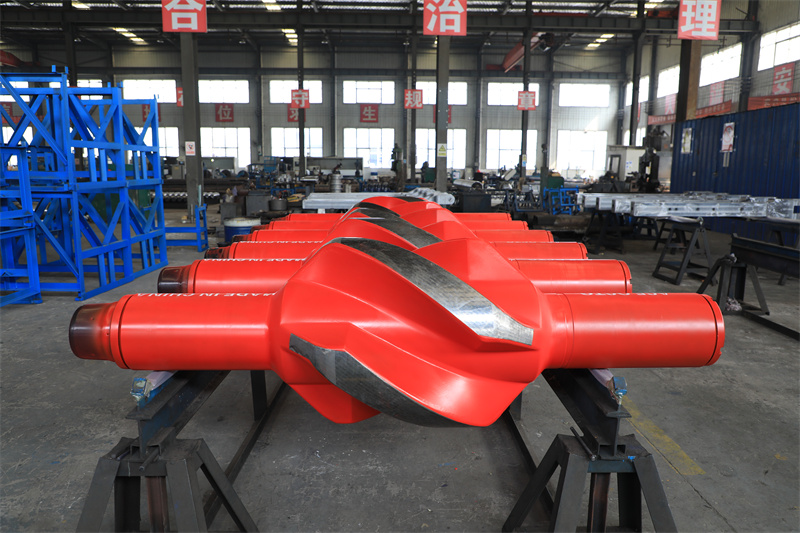

Near Bit Or String HF-3000 Stabilizer

Product Video

Near bit or string HF-3000 stabilizer advantage of WELONG

• HF-3000 Stabilizer is customized, stabilizer forging and final stabilizer are available from us.

• Material steel mill is audited per biennium and approved from our company WELONG.

• There is stock(≤24” )of stabilizer material, the machining delivery time is about one month.

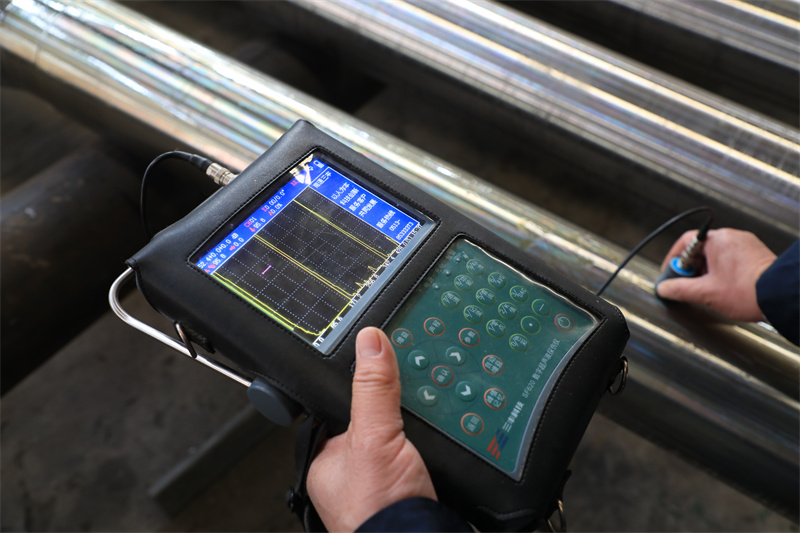

• Each stabilizer has 5 times nondestructive examination (NDE).

HF-3000 hard facing introduction

Tungsten carbide inserts sets in a power spray deposit ideal for abrasive formations. 97% bonding guaranteed, certified by ultrasonic reports. This kind is recommended for non-magnetic stabilizer. The exact composition and properties of HF-3000 can vary depending on the manufacturer. However, in general, it is designed to provide superior wear resistance, hardness, and durability to the underlying metal surface. HF-3000 hard facing is typically applied using various welding techniques, thermal spraying, or other deposition methods. The goal is to create a protective layer that can withstand abrasive, erosive, or corrosive conditions. This makes it suitable for use in industries such as mining, construction, oil and gas, agriculture, and manufacturing, where machinery and components are exposed to extreme wear and harsh environments.

Near bit or string HF-3000 stabilizer dimension

|

Working OD In(mm) |

Fishing Neck Size In(mm) |

Top Thread API |

Bottom Thread API |

ID Size In(mm) |

Fishing Neck Length In(mm) |

Blade Length In(mm) |

Blade Width In(mm) |

Overall Length In(mm) |

Note |

|

5-7/8 (142.9) |

4-3/4 (120.7) |

3-1/2 IF |

3-1/2IF 3-1/2 REG |

2-1/4 (57.2) |

28 (711.2) |

16(406) |

2-1/4 (57.2) |

72 (1828.8) |

String Near bit |

|

8-1/2 (215.9) |

6-1/2 (165.1) |

4-1/2 IF |

4-1/2IF 4-1/2 REG |

2-13/16 (71.4) |

28 (711.2) |

16 (406) |

2-3/8 (60.3) |

72 (1828.8) |

String Near bit |

|

12-1/2 (311.1) |

8-1/4 (209.6) |

6-5/8REG |

6-5/8REG |

2-13/16 (71.4) |

30 (762) |

18 (457) |

3 (76.2) |

90 (2286) |

String Near bit |

|

17-1/2 (444.5) |

9 (228.6) |

6-5/8REG |

6-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

90 (2286) |

String Near bit |

|

22 (558.8) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

100 (2540) |

String Near bit |

|

26 (660.4) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

100 (2540) |

String Near bit |

|

36 (914.4) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

119 (2946.4) |

String Near bit |

Customized Service

Standard material grade

Customized material grade-differs in chemical and mechanical property

Customized Shape

Customized marking and package

Multiple payment term: T/T, LC, etc

Production Process

Order Confirmation in 1-2 days

Engineering

Production Planning

Raw Material Preparing

Incoming Material Inspection

Rough Machining

Heat Treatment

Mechanical Property Test

Finish turning

Final Inspection

Painting

Package & Logistic

Quality Control

5-times UT

Third Party Inspection

Good Service

Endurable products & Stable price.

Supply multiple inspections, UT, MT, X-ray, etc

Always react to customer’s urgent need.

Customized logo and package.

Optimize customer design & solutions.

Prefer to suggest more options than say no to customers.

Help customer group delivery in the whole China.

Less empiricism, more learning with open mind.

Online meeting freely via Teams, Zooms, Whatsapp, Wechat, etc

Customers

Delivery

20-years experiences with forwarders

Multiple shipping: Air transit/Sea shipping/Courier/etc

Arrange reliable and direct vessel within 1 week

Can cooperate on FOB/CIF/DAP/DDU, etc

Complete shipping documents for customs clearance