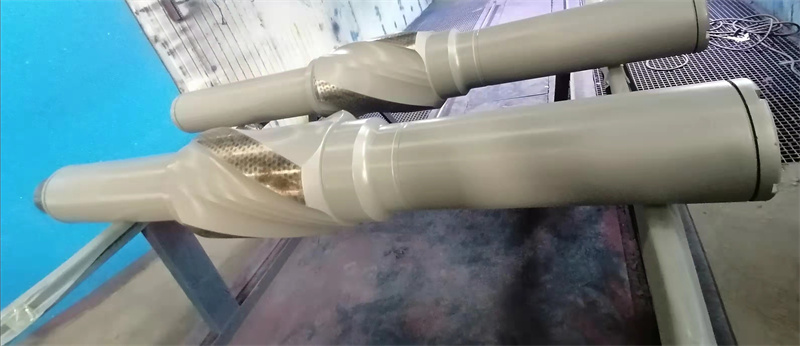

Customized Sleeve Stabilizer

Customized sleeve stabilizer advantage of WELONG

• Sleeve Stabilizer is customized, stabilizer forging and final stabilizer are available from us.

• Material steel mill is audited per biennium and approved from our company WELONG.

• There is stock(≤24” )of stabilizer material, the machining delivery time is about one month.

• Each stabilizer has 5 times nondestructive examination (NDE).

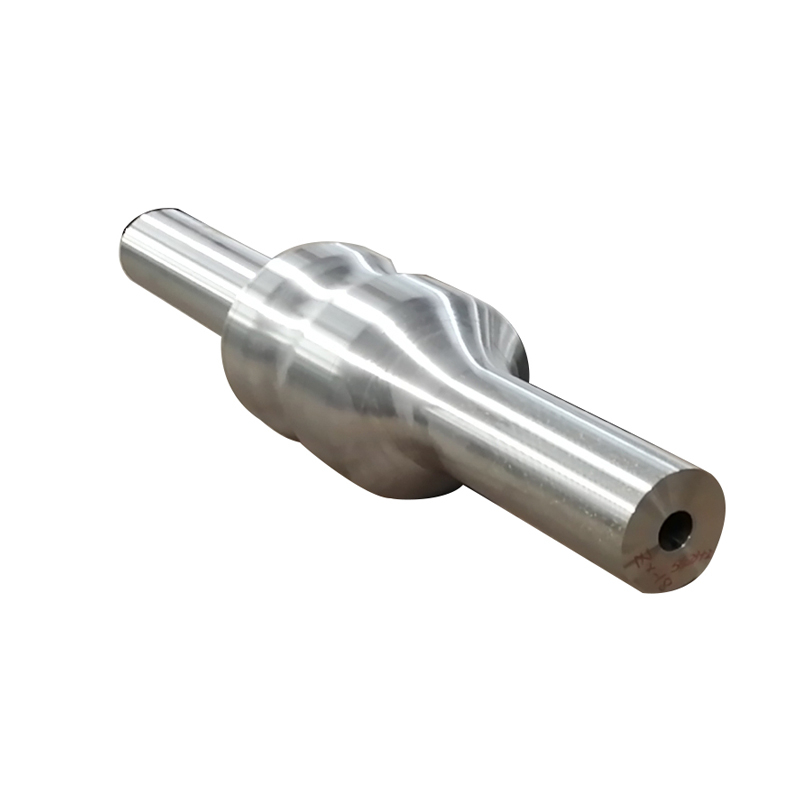

Customized sleeve stabilizer introductions

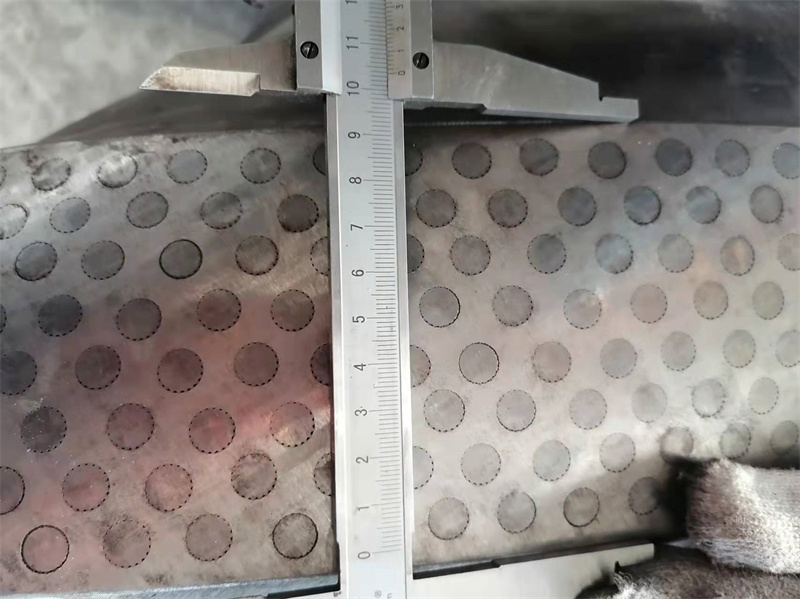

• Sleeve stabilizer hard facing is optional, such as API standard HF-1000, HF-2000, HF-3000, HF-4000, HF-5000 or customized.

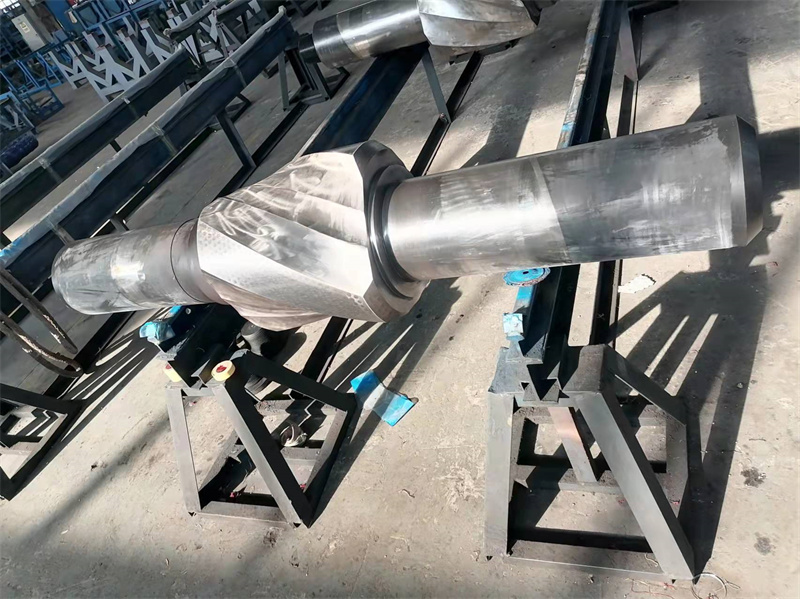

Process of sleeve stabilizer Process

Forging + Rough machining + Heat Treatment +Property Self-Testing + The third-party testing + Finishing Machining + hard facing welding +painting+ Final inspection + Packing.

Customized sleeve stabilizer dimension

|

Working OD In(mm) |

Fishing Neck Size In(mm) |

Top Thread API |

Bottom Thread API |

ID Size In(mm) |

Fishing Neck Length In(mm) |

Blade Length In(mm) |

Blade Width In(mm) |

Overall Length In(mm) |

Note |

|

8-1/2 (215.9) |

6-1/2 (165.1) |

4-1/2 IF |

4-1/2IF 4-1/2 REG |

2-13/16 (71.4) |

28 (711.2) |

16 (406) |

2-3/8 (60.3) |

72 (1828.8) |

String Near bit |

|

12-1/2 (311.1) |

8-1/4 (209.6) |

6-5/8REG |

6-5/8REG |

2-13/16 (71.4) |

30 (762) |

18 (457) |

3 (76.2) |

90 (2286) |

String Near bit |

|

17-1/2 (444.5) |

9 (228.6) |

6-5/8REG |

6-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

90 (2286) |

String Near bit |

|

22 (558.8) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

100 (2540) |

String Near bit |

|

26 (660.4) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

100 (2540) |

String Near bit |

|

36 (914.4) |

9-1/2 (241.3) |

7-5/8REG |

7-5/8REG |

3 (76.2) |

30 (762) |

20 (508) |

4 (101.6) |

119 (2946.4) |

String Near bit |

Sleeve Stabilizer application

Sleeve Stabilizer dimension Wellhead operation: A sleeve stabilizer can be used for drilling and completion of oil wells. They can help install and secure casing, drill pipes, and other critical equipment, ensuring the stability and safety of the wellhead.

Sleeve repair: When there is a problem with the sleeve, a sleeve stabilizer can be used to repair and maintain the sleeve. They can help reposition and secure the casing, solve water leaks, cracks, or other damage situations, and ensure the sealing of the wellhead and good wellbore conditions.

Pipeline connection: The sleeve stabilizer can be used for straightening and positioning during pipeline connection and docking. They ensure the correct alignment of the pipeline, prevent deflection and leakage, and provide stable connections.

Underground medium control: In the process of oil extraction and water injection, the sleeve stabilizer also plays an important role. They can be used to insert and position various control devices, such as valves, measuring instruments, and sensors, to achieve monitoring and control of underground media.

Downhole workover: When downhole workovers and operations are required, a sleeve stabilizer can help install and fix workover tools and equipment. They ensure the correct alignment and stability of tools, improve construction efficiency and success rate.