Industry News

-

WELONG shaft forgings for large hydro-generator

Forged Material: 20MnNi and 20MnNi. Mechanical Properties: For a forging thickness (T) between 300mm < T ≤ 500mm, the material 20MnNi should have a yield strength ≥ 265MPa, tensile strength ≥ 515MPa, elongation after fracture ≥ 21%, reduction of area ≥ 35%, impact absorption energy (0℃) ≥ 30J...Read more -

WELONG forgings for large gear and gear ring

Regarding WELONG forgings for large gear and gear ring, please refer to following information. 1 Ordering requirements: The name of the forging, material grade, quantity of supply, and delivery status should be specified by both the supplier and the buyer. Clear technical requirements, inspectio...Read more -

Why does the forging industry need to change after the COVID-19?

The COVID-19 has had a huge impact on the global economy and industrial chain, and all industries are rethinking and adjusting their own development strategies. The forging industry, as an important manufacturing sector, is also facing many challenges and changes after the epidemic. This article ...Read more -

How to increase Forging Production?

The increase in forging production involves multiple aspects of optimizing forging processes, aiming to improve efficiency, reduce costs, and enhance overall productivity. The following are some strategies that need to be considered to achieve this goal: Optimize forging process: Analyze t...Read more -

Forging Non-Destructive Testing

Non-Destructive Testing (NDT) is a technique used to detect internal defects in materials or components without compromising their integrity. For industrial components such as forgings, non-destructive testing plays an important role in ensuring quality and reliability. The following are several ...Read more -

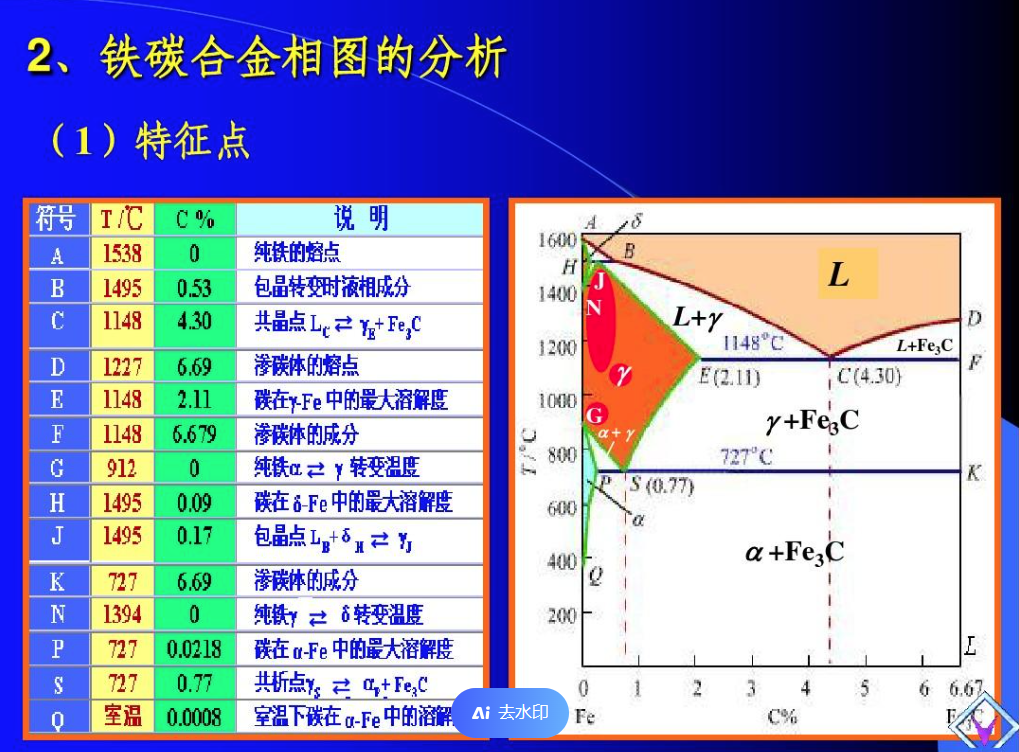

Is it enough to learn the iron carbon equilibrium phase diagram well in heat treatment work?

Heat treatment is a commonly used method in metal material processing, which changes the microstructure and properties of materials by controlling their heating and cooling processes. The iron carbon equilibrium phase diagram is an important tool for studying the microstructure transformation law...Read more -

When quenched workpiece has not cooled to room temperature and cannot be tempered?

Quenching is an important method in metal heat treatment, which changes the physical and mechanical properties of materials through rapid cooling. During the quenching process, the workpiece undergoes stages such as high-temperature heating, insulation, and rapid cooling. When the workpiece is ra...Read more -

Why cannot the hardness requirements specified in the material manual be achieved?

The following reasons may result in the inability to meet the hardness requirements specified in the material manual after heat treatment: Process parameter issue: Heat treatment is a complex process that requires strict control of process parameters such as temperature, time, and cooling ...Read more -

How many more heat treatments can be performed after the heat treatment performance of the forging is unqualified?

Heat treatment is a process of improving the properties and structure of metal materials through heating and cooling. Heat treatment is an indispensable step in the production process of forgings. However, sometimes due to various reasons, the heat treatment results of forgings may not meet the r...Read more -

Steel Forgings for Ship

Material of this forged part: 14CrNi3MoV (921D), suitable for steel forgings with a thickness not exceeding 130mm used in ships. Manufacturing process: The forged steel should be smelted using electric furnace and electric slag remelting method, or other methods approved by the demand side. The s...Read more -

FORGING Magnetic Particle Testing (MT)

Principle: After ferromagnetic materials and workpieces are magnetized, due to the presence of discontinuities, the magnetic field lines on the surface and near the surface of the workpieces undergo local distortion, resulting in leakage magnetic fields. Magnetic particles applied to the surface ...Read more -

Forgings of Nozzle Holder Body for Common Rail System

1. Process Specifications 1.1 It is recommended to use vertical closed-die forging process to ensure a streamlined distribution along the outer shape of the forged part. 1.2 The general process flow includes material cutting, weight distribution, shot blasting, pre-lubrication, heating, forging, ...Read more