The Negatives of Open Die Forging: Exploring the Disadvantages of this Manufacturing Technique.

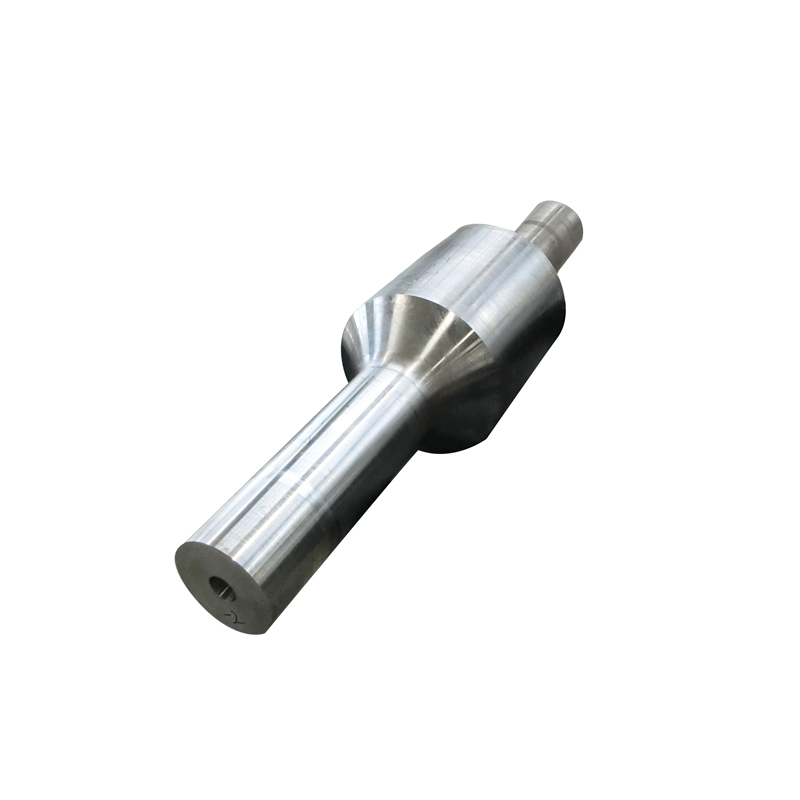

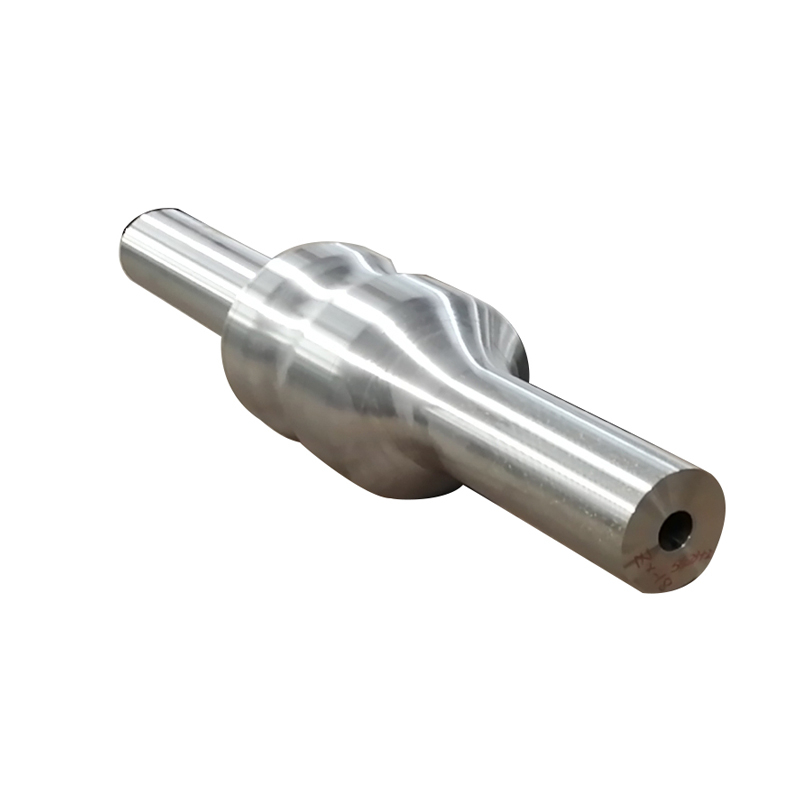

Shaanxi WELONG Int'l Supply Chain Mgt Co., Ltd. takes pride in being a leading manufacturer, supplier, and factory specializing in high-quality open die forging products. We understand the essential role that forging plays in various industries, and therefore, we strive to provide reliable and impeccable products to our clients. Open die forging is a widely adopted manufacturing technique, owing to its numerous advantages. It allows for the production of customized and intricate components that offer exceptional strength, durability, and precise dimensional control. This forging method also enhances the material's microstructure, ensuring optimal mechanical properties. However, it is crucial to consider the disadvantages associated with open die forging to make informed decisions. Despite its unmatched versatility, this technique does not provide intricate geometries and close tolerances as achieved in closed die forging. Additionally, the absence of complete cavity confinement may lead to non-uniform metal flow, resulting in minor surface imperfections. At Shaanxi WELONG, we understand these drawbacks and work meticulously to minimize their impact. Our team of skilled professionals uses advanced technology, state-of-the-art equipment, and stringent quality control measures to overcome the disadvantages of open die forging. Rest assured, our products undergo rigorous testing to meet and exceed industry standards. Choose Shaanxi WELONG as your trusted partner for high-quality open die forging products. We guarantee exceptional craftsmanship, reliable performance, and an unwavering commitment to customer satisfaction. Contact us today to experience the excellence in open die forging.

Related Products

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

Top