Exploring the Differences: Open Die Forging vs. Closed Die Forging , [Your Brand Name]

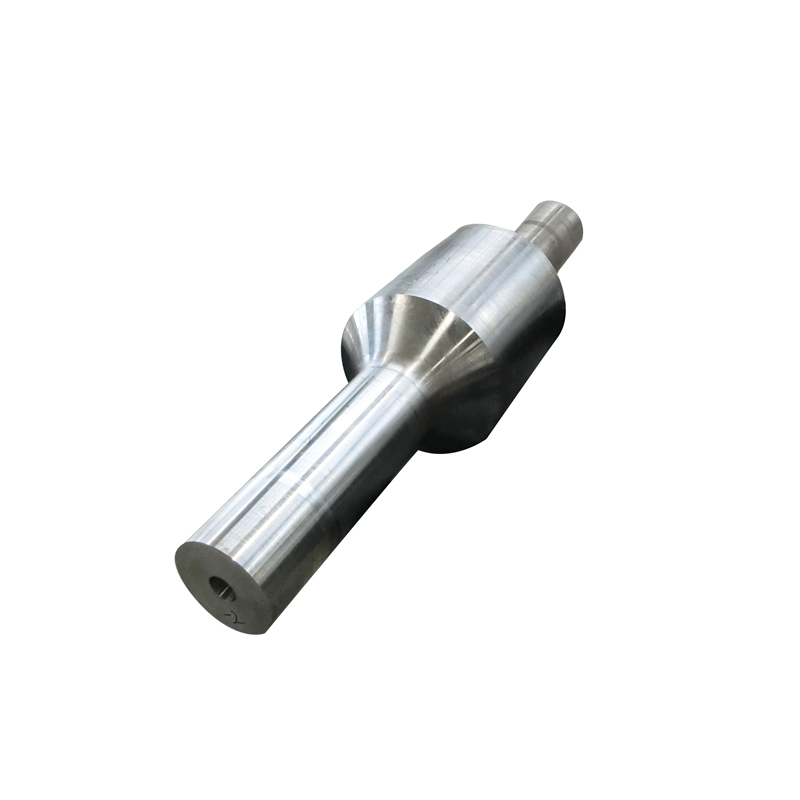

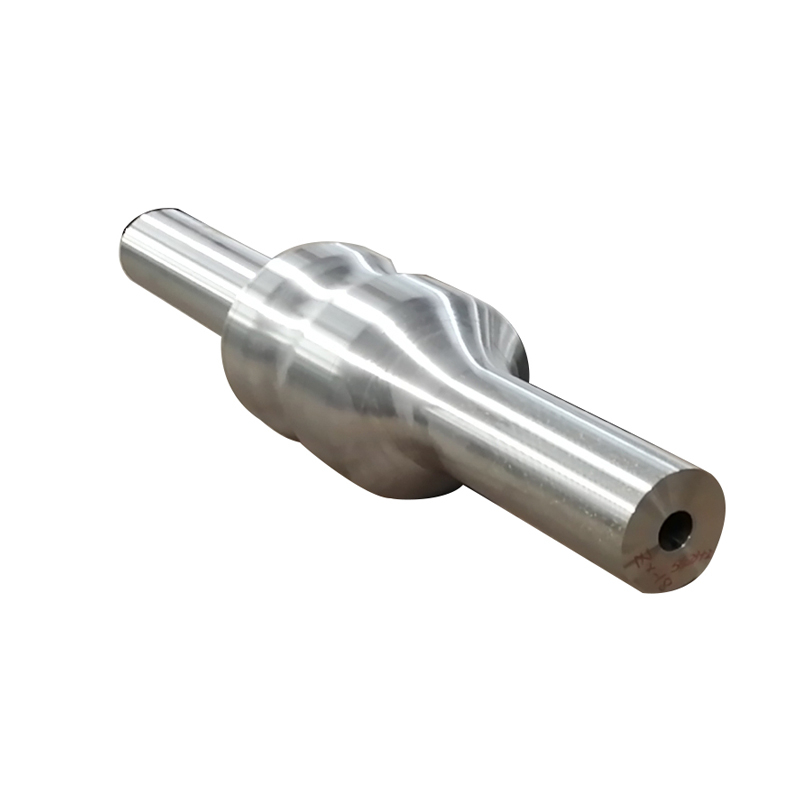

Shaanxi Welong Int'l Supply Chain Mgt Co., Ltd. takes pride in being a leading manufacturer, supplier, and factory of high-quality forgings. Our expertise lies in two distinct processes: open die forging and closed die forging. These techniques offer unique advantages and cater to the diverse needs of our esteemed customers. Open die forging involves shaping metal by applying compressive forces between multiple dies. This method allows for the production of forgings with complex shapes and sizes, offering maximum flexibility and customization. On the other hand, closed die forging utilizes impressions created by precision-machined dies to shape the metal. This technique ensures tighter tolerances, excellent surface finish, and increased strength in the final product. At Shaanxi Welong, our skilled team of craftsmen employ the latest technology and machinery to deliver forge products that meet the highest industry standards. With a comprehensive range of material options and the ability to accommodate various order volumes, we can cater to the requirements of diverse industries. When it comes to high-quality forgings, Shaanxi Welong Int'l Supply Chain Mgt Co., Ltd. is your trusted partner. Contact us today to discuss your forging needs and experience the excellence and reliability that our products bring to your applications.

Related Products

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

Top